Manufacturing Information Systems (MIS)

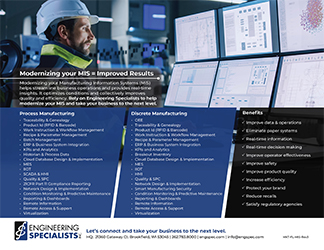

Modernizing your MIS = Improved Results

Modernizing your Manufacturing Information Systems (MIS) helps streamline business operations and provides real-time insights. It optimizes conditions and collectively improves quality and efficiency. Rely on Engineering Specialists to help modernize your MIS and take your business to the next level.

Benefits to Modernizing your Manufacturing Information Systems (MIS)

Improve data and operations

Eliminate paper systems

Real-time information

Real-time decision making

Increase efficiency

Improve operator effectiveness

Protect your brand

Satisfy regulatory agencies

Improve product quality

Reduce recalls

Improve safety